Countersunk Rivet Nuts vs Regular Rivet Nuts:

Which is Better?

When it comes to fastening materials together, rivet nuts or Rivnuts®, are a popular choice. But when should you choose countersunk rivet nuts over regular rivet nuts? This guide will help you understand the differences between the two and make an informed decision for your specific needs.

What are Rivet Nuts?

Rivet nuts, also known as threaded inserts, Rivnuts®, and nutserts, are fasteners that are used to join two or more materials together. Rivet nuts are installed into the parent material and then a secondary attachment is bolted onto the parent material by threading into the rivet nut. Rivet nuts are commonly used in applications where a strong joint is required, but access to the back of the parent material is limited (also called, “blind”) and there is a desire to be able to remove the secondary application from the primary (parent) application. Rivet nuts are “installed” with special tooling that pulls the rivet nut to expand and grip the backside of the parent material. Rivet nuts are typically made from materials such as aluminum, steel, or stainless steel, and come in a variety of sizes (M4 thru M12, 4-40 thru 1/2-13) and shapes (round or hex body, open or closed end, thick head or thin head, etc.) to suit different applications.

What are Regular Rivet Nuts?

Regular rivet nuts, also known as flat head rivet nuts, are the most commonly used type of rivet nut. These are considered the “original” rivet nut and are widely used in all applications throughout the world, especially heavy-duty construction or industrial applications. A regular rivet nut is shown below and has the following characteristics:

- Circular medium thickness flat head (not a thick head, not a thin head, not a countersunk head).

- Round with a smooth body (not a hex body, not a half-hex body, not a knurled or ribbed body).

- Made of steel material (not stainless, not aluminum).

- Open end body construction (not a closed end body construction)

What are Countersunk Rivet Nuts?

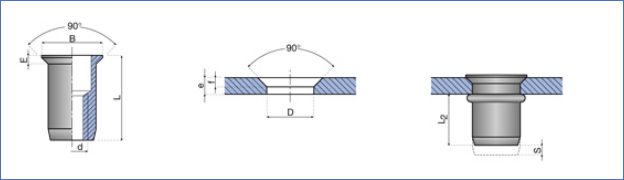

Countersunk Rivet Nuts (also called Rivnuts®) are substantially similar to a regular rivet nut, except that the head is COUNTERSUNK to seat flush after being installed into the surface of the parent material! They are commonly used in applications where a smooth, flush finish is required, such as in automotive (think, “mounting the dashboard for a sleek appearance”) or aerospace applications (think, “smooth surfaces of an airplane for best aerodynamics”). Countersunk rivet nuts are installed the same way a regular rivet nut is installed, however, the hole the countersunk rivet nut is dropped into must also be countersunk or it will not seat flush with the surface. Countersunk rivet nuts require the parent material to be slightly thicker than a regular rivet nut, due the fact that the rivet nut hole must be drilled a countersunk hole, which removes a bit more of the parent material when countersinking the hole. A unified threaded countersunk head usually is 100° angle, with metric threaded countersunk had usually is 90° angle.

Pros and Cons of

Countersunk Rivet Nuts.

Regular rivet nuts, also known as flat head rivet nuts, have a flat head that sits above the surface of the material. This makes them easier to install, as they do not require a countersink hole. Regular rivet nuts also tend to be more resistant to PUSH THROUGH than countersunk rivet nuts, as the flat head provides more grip on the top side of the material. However, the protruding head may not be desirable for applications where a smooth, flush finish is desired (i.e., aerodynamics). It ultimately depends on the specific needs of your project.

Help to Choose Between Countersunk Rivet Nuts and Regular Rivet Nuts.

When you are unsure if a countersunk rivet nut is the appropriate fastener for your specific application, contact Rivet Nut USA to speak to one of their knowledgeable rivet nut experts. They will go over all details of your application and help you choose if a countersunk rivet nut, or nutsert, will be ideal for your individual application.