3 Bollhoff RIVCLINCH® Systems

RIVCLINCH®: Metal joining without fasteners

Automation E System: When clinching electrifies – energy efficient & flexible

Download the Automation E Catalog

APF System: Automatic pocket filter solution

Download the APF Catalog

Videos

Bollhoff RIVCLINCH® process of joining metal without fasteners

RIVCLINCH®: Metal Joining Systems

Fast. Reliable. Tool-Free Metal Joining.

Bollhoff RIVCLINCH® is an advanced mechanical joining technology engineered for fast and secure assembly of metals —without the use of fasteners, adhesives, or heat. The RIVCLINCH® process uses cold forming to permanently interlock two or more layers of metal through a precisely formed round or square indentation. This results in a strong, clean, and environmentally friendly application.

The Bollhoff RIVCLINCH® creates strong, durable joints that maintain material integrity and surface coatings. The diagram illustrates two types of RIVCLINCH® joints, each suited to different applications and material requirements.

The LEFT SIDE of the diagram shows a round joint which can only be created by deformation. It is water and gas tight. It protects the coating and provides high corrosion and fatigue resistance. Additionally, it is visually pleasing.

The RIGHT SIDE of the diagram shows a rectangular joint which is the result of a combination of cutting and deforming. It is ideal for thick or harder materials such as stainless steel.

Diagram of the two materials after being permanently compressed/joined together by the Rivclinch® tool.

Efficient

Fast Cycle Time

Interlock parts in under one second—ideal for high-volume production.

No Fasteners or Adhesives Needed

Eliminate the cost, weight, and additional steps of welding, glueing, or using fasteners.

Increased Joint Strength

The clinching process enhances mechanical strength near the joint.

Economical

Multi-Material Compatibility

Joins steel, stainless steel, coated or painted steels, and aluminum.

Easy to Automate

No skilled labor required. Easily integrates with automated production lines.

High Repeatability

Consistent, high-volume manufacturing with minimal maintenance.

Eco-Friendly

Sustainable Solution

No harsh chemicals, no fumes, no heat—making it safe for operators and eco-conscious for the environment.

Low Energy Use

Uses 20 times less electricity than welding.

Clean

No pre-cleaning or post treatment required after installation.

- Automation E: modular electrical lightweight system

- 201IP: Flexible setting, lightweight clinching tool

- 0404 IP: Flexible setting, lightweight clinching tool for the construction industry

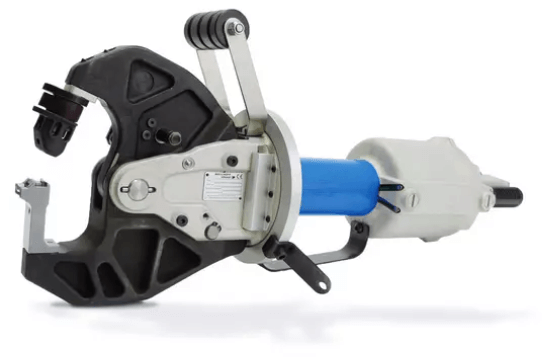

- 706 IP: Pneumatic, high-performing clinching tool with large jaws for opening and clinching thicker material

- 4006 P50 PASS: Pneumatic, cost-effective, and flexible clinching machine

- 0201 FS: Lightest and fastest clinching tool with special 360 degrees rotating ability

- 0501 FS: Portable and lightweight clinching tool for edges, corners, and flat panels.

Flexible Clinching System Options

Available in multiple configurations to suit your workflow:

- Portable Tools

- Stand-Alone Units

- Fully Automated Systems

- Robot-Mounted with Process Control

Each RIVCLINCH ® system runs on air and hydraulic power. It has a part that moves forward using air pressure, and you can adjust it separately from the main part that does the work. This adjustable setup makes RIVCLINCH® perfect for jobs where the distance between joining points varies. The result is reliable sheet metal joining without fasteners, providing consistent strength and precision in both round joint and rectangular joint configurations.

Application & Industries

RIVCLINCH ® is used across a wide range of industries, including:

- Automotive & Transportation

- HVAC & Air Duct Systems

- Appliances

- Building & Construction

- Electronics & Lighting

- Energy & Solar

- Sheet Metal Fabrication

- Vending & Retail Equipment

- Door & Gate Manufacturing

- Scaffolding, Ladders & More!

Contact Rivet Nut USA™, a division of Cardinal Components, Inc., today to speak with one of our knowledgeable customer service team members to help you revolutionize your assembly process with Bollhoff RIVCLINCH ® installation tooling. Rivet Nut USA™ is the premier distributor of Bollhoff products and we stock our inventory to provide you the best availability and variety. Request a quote today!