Proper Hole Quality Rivets | Rivet Nuts

Achieving proper hole quality for rivets and rivet nuts is essential for installation. A clean hole ensures that the fastener sits evenly and is properly aligned, which is critical for secure and lasting performance. Any burrs inside the hole or blowout on the backside (blindside) can cause the fastener to sit at an angle, resulting in a crooked installation. Such misalignment can lead to poor load distribution, increasing the risk of issues like spin out or pull out under stress. Ensuring a clean, burr-free hole surface helps the fastener grip securely, extending its operational lifespan and enhancing the overall strength of the connection.

DRILLING HOLES: LOW-TO-MEDIUM VOLUME ROUND HOLES

When drilling holes manually, it’s crucial to let the drill bit do the cutting work without forcing it through the material. Forcing a drill can lead to rough edges or blowout on the backside of the hole, especially in thinner materials. To reduce blowout, it’s often beneficial to drill a smaller pilot hole before expanding to the final larger hole size. This step-by-step approach provides more control, resulting in a cleaner finish. Also, using an oil or other type of lubrication to keep the drill and material from getting too hot and melting will help keep the drill bit cutting and reduce risk of slag or burrs. Clean, burr-free holes contribute significantly to the overall performance and durability of riveted joints, reducing the risk of fastener failure over time.

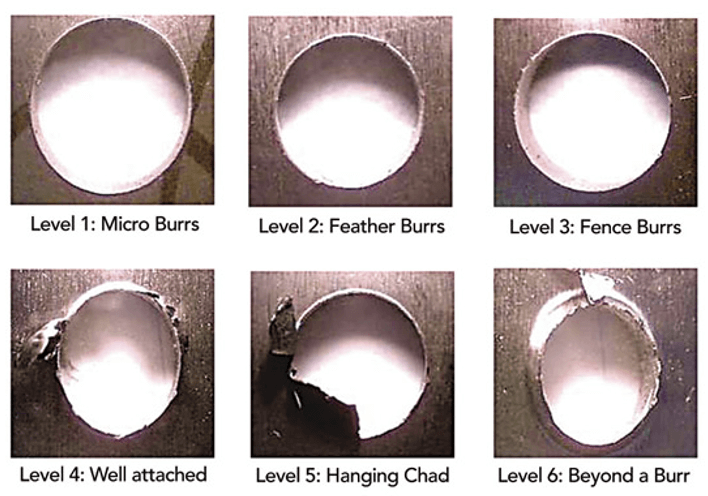

There are basically six types of improperly drilled holes that create damage to the material, which risks faulty installation of your rivet nut. The image below displays those examples with levels 1-6. Levels 1-3, although not severe will create an increased amount of material thickness around the drilled hole because of the burr (or ridge) that is created. This burr will cause your rivet nut to install unevenly due to the ridge, or fence, that sits on top of the edge of the hole making the edge thicker than the rest of the material. When the rivet nut is installed it is not joining to a flat surface. Levels 4-6 are so severe that the material around the hole can be broken off and will significantly change the shape of the hole itself. This level of severity will make it impossible to install the rivet nut tightly to the parent material.

Example of various unacceptable or bad holes (with blowout and burrs).

Image credit to Cutting Tool Engineering (https://www.ctemag.com/)

LASER MACHINE TO CREATE HOLES: HIGH VOLUME INSTALLATION OR HEX HOLES

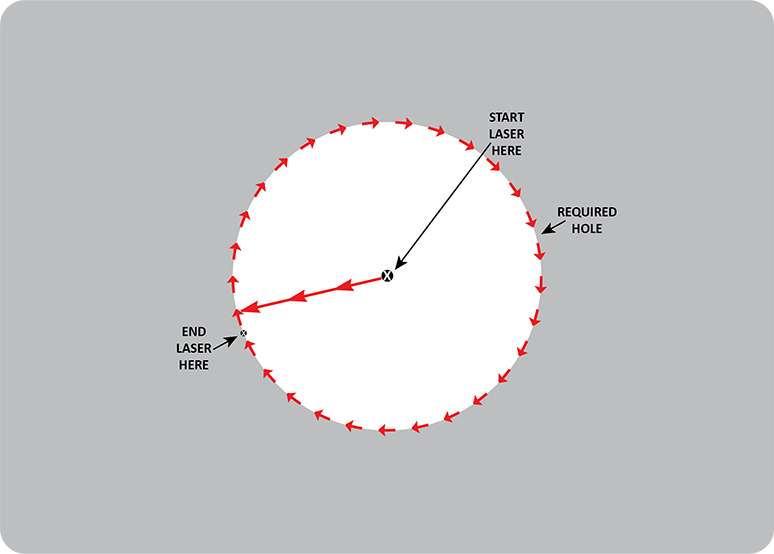

Laser cutting is ideal for creating precise, clean holes, but the technique requires care. To avoid imperfections like slag, it’s best to start the laser at the center of the intended hole. From there, guide the laser outward to the edge, and then move it in a smooth, continuous 360-degree motion. This approach prevents the buildup of hardened material (slag) on the hole’s edge, which can otherwise interfere with the fastener’s seating and may compromise the rivet’s or rivet nut’s grip strength. With proper technique, laser cutting produces holes with smooth edges that promote accurate and stable fastener installations.

Example of how to start and stop a laser that is cutting a round hole.

PUNCH TO CREATE HOLES: HIGH VOLUME INSTALLATION OR HEX HOLES

Punching holes is an efficient method for creating fastener holes in high-volume applications, especially in thinner gauge metals or when hex-shaped holes are required for hex-shaped rivet nuts. Using a sharp punch and die to shear the material, punching produces holes quickly and consistently making it ideal for production environments where speed and uniformity are essential. However, keeping the punch sharp is key to avoiding burrs or deformity, which could impact fastener performance. This method is especially suited for softer metals and precise shapes, like hex holes, which offer better resistance to rotation than standard round rivet nuts. Please send us an email if you’d like a quote on our top-of-the-line hex hole punch tool to help ensure proper hole quality for rivets and rivet nuts our 9991 Pneumatic Hex Hole Cutting Tool.

Visit our Rivet and Rivet Nut product pages for more information!

We offer high-quality Rivets and Rivet Nuts suitable for various industrial and domestic applications. Choosing the right Rivet Nut for your application can sometimes be complex. That’s why Rivet Nut USA™, a division of Cardinal Components, Inc., provides expert support to assist you in selecting the best fastening solution. Our knowledgeable team is available to answer questions, provide guidance on product specifications, and help you navigate through our extensive inventory to find the right Rivet Nut for your project.

For more information on Rivets and Rivet Nuts or to get a quote, contact Rivet Nut USA™ today!