If you don’t see exactly what you want in the catalog, we can make a custom variant for you!

Download the Eco Product Catalog

Download the Metal Product Catalog

Videos

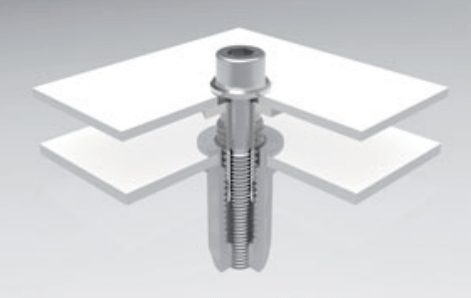

Bollhoff FLEXITOL® Metal Tolerance System

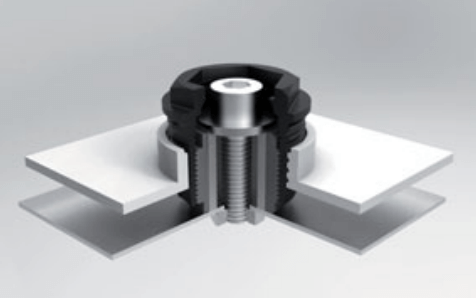

Bollhoff FLEXITOL® Hybrid Tolerance System

FLEXITOL® for more Tolerance and Less Expense

Bollhoff FLEXITOL® is an assembly system that adjusts for variations in part size or position for a smooth and continuous production line. This gives the application a more precise fit, reducing the need for manual reworking of the process. In complex manufacturing, like Flexitol in automotive and construction environments, small part variations can cause misalignment or gaps. FLEXITOL® helps fix these issues. This advanced system is designed to simplify assembly, promote high-quality results, and help reduce costs while expanding overall Flexitol uses across demanding applications.

Benefits

- Compensates wide tolerances, enabling more flexible production.

- High performance reliability and consistent quality.

- Accessible from one side, simplifying installation in tight applications.

- Quick and easy installation helps keep cycle-times short.

FLEXITOL® is available in both manual and automatic versions, and across several design families: metal, hybrid, and plastic, supporting a wide range of Flexitol uses in manufacturing.

Manual tolerance compensation

In the Manual Version, the adjustment is made by setting the screw depth during installation. When the parts are being joined, FLEXITOL® compensates for any differences in their size or position. It’s best for applications where parts are aligned by hand.

Automatic tolerance compensation

The Automatic Version lines up two parts with each other. When they are screwed together, the system automatically adjusts to help remove any gap between them. It then locks the parts in the position where they were aligned. When the connection is loosened, the system returns to its original starting position. It’s ideal for mass production and when only one-side of the application is accessible.

FLEXITOL® Metal: A two-component all-metal system, highly wear-resistant and great for compact spaces. Designed for installation in existing applications and tough environments.

FLEXITOL® Hybrid: Combines strong metal parts with a plastic nut holder. Designed for high-volume production with flexible installation heights and easy adjustment.

FLEXITOL® Plastic: A pre-assembled plastic component for applications where a lightweight or non-metallic solution is required.

FLEXITOL® K’ in K’ system is designed for use with banjo screws—special fasteners often used in fluid or hydraulic connections. The screw cuts its own matching threads into the plastic as you tighten it.

FLEXITOL® Eco uses a plastic cage with a built-in metal nut that automatically adjusts to part variations when it is tightened. No extra steps needed! Its clip design keeps the fastener in place during transport, making it easy to pre-assemble—ideal for securing things like vehicle dash panels.

FLEXITOL® for rear light attachment is a special mounting or fastening system (called FLEXITOL®) used to attach a rear light—likely in a vehicle, bicycle, or similar product. It lets you fine-tune the rear light’s position, so it fits perfectly and looks precise.

FLEXITOL® for Roof Rail Attachment provides a special way to attach roof rails by adjusting for small fitting differences automatically or by hand. It safely transfers the load to stronger metal layers underneath, so roof thickness variations don’t affect the fit or gap.

Bollhoff FLEXITOL® is widely proven across industries. Applications include:

- Automotive: Headlights, Body components, door and seat frames, roof parts and more!

- Construction: Metal Roof Rails

- Large plastic cover installation and other modules needing alignment and compensation.

Ready to optimize your assembly with FLEXITOL®? Contact Rivet Nut USA™, a division of Cardinal Components, Inc., to speak with one of our fastener specialists to explore the best variant for your application, request a quote, or discuss custom sizing and design support! Tooling is also available for high-volume production, just ask!