Videos

Bollhoff Onsert | Threaded Insert Application

Bollhoff Onsert | Stud Application

Adhesive Fasteners That Bond Without Welding or Drilling

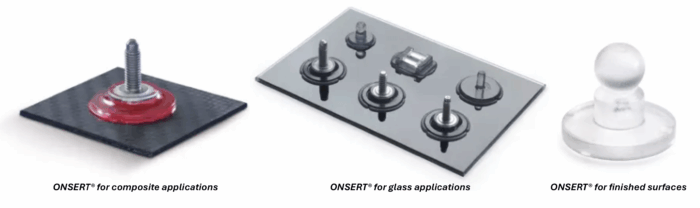

The Bollhoff ONSERT® system lets you attach fasteners — like threaded inserts or studs & couplings — to a variety of surfaces using a special light-curing adhesive instead of welding or using mechanical force, like with drilling. With Bollhoff ONSERT®, you can typically create a reliable, high-strength connection in just seconds! This method is ideal for lightweight materials such as carbon fiber, aluminum, plastic, or glass. It works especially well when you can’t reach the back of the part or when drilling and welding could damage the material. In the right conditions, there is also the ability to remove the ONSERT® and replace it with a new ONSERT® without damaging the parent application, making this fastener versatile and easy to maintain.

The ONSERT® system helps designers and manufacturers save time, reduce weight, and protect materials. It gives engineers more freedom to work with advanced composites and coatings, without worrying about damaging them. These adhesive bonded fasteners offer a clean, lightweight alternative to welding or traditional mechanical fasteners.

The ONSERT® system helps designers and manufacturers save time, reduce weight, and protect materials. It gives engineers more freedom to work with advanced composites and coatings, without worrying about damaging them. These adhesive bonded fasteners offer a clean, lightweight alternative to welding or traditional mechanical fasteners.

Whether installed by hand or through an automated production line, ONSERT® delivers a clean, efficient fastening solution — with no compromise in strength.

- Fast installation: In most situations, the adhesive cures in about 4 seconds.

- No damage to materials: Works without deforming or adding additional substances to the workpiece.

- Strong and reliable: Supports mechanical loads right after curing.

- Lightweight design: Perfect for advanced materials and thin panels.

- Clean look: The fastener sits on the surface — no marks or backside access needed.

- Flexible design: Works with many shapes, including inserts, studs, and custom fasteners.

How It Works

The ONSERT® process is simple and fast:

- Apply adhesive to the bottom of the fastener.

- Place and align the fastener on the surface with a handheld or automated tool.

- Cure with light — the adhesive hardens quickly, most times in just a few seconds.

- Ready to use — once cured, the fastener can handle full loads immediately.

The clear base of the fastener allows the light to pass through, creating a strong, reliable bond without heat or holes.

The preferred adhesive used with the Bollhoff ONSERT® is the DELO PHOTOBOND. They work together to provide optimal fastening performance. Rivet Nut USA™ or Bollhoff can stock the DELO PHOTOBOND adhesive for convenience when you are ordering the ONSERT® system! Ask one of our customer team members about the DELO PHOTOBOND!

- ONSERT® Smart: A fast, easy-to-use version for light-curing adhesives.

- ONSERT® SL ONE: A handheld LED system for smaller jobs or hard-to-reach areas.

- ONSERT® Automation: Fully automated system for high-volume production, with curing times as quick as 1.5 seconds.

The ONSERT® process is already widely used in industries where installation efficiency and application weight are most important:

- Automotive and electric vehicles: For bonding mounts and clips to painted or composite parts.

- Aerospace: For attaching parts to panels when the back side isn’t accessible.

- Electronics and appliances: For smooth, coated, or glass surfaces.

- General manufacturing: Anywhere traditional fasteners won’t work due to material or space limits.

For more information, read our article: What is the Bollhoff ONSERT®?

Want to learn more about these adhesive bonded fasteners? As an authorized Bollhoff distributor, Rivet Nut USA™, a division of Cardinal Components, Inc., offers the ONSERT® fastening system with expert support and fast turnaround times. Ask us about the DELO PHOTOBOND adhesive option that can be provided for your application. Contact our team today to request a quote or get more information!